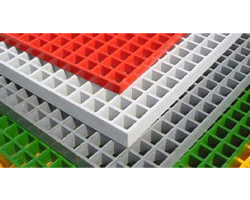

Gratings are used in a wide range of industrial applications for purposes such as filtration, separation, support, drainage, and ventilation. The choice of grating depends on the application, environment, and required mechanical or chemical properties. Here are the different types of industrial gratings:

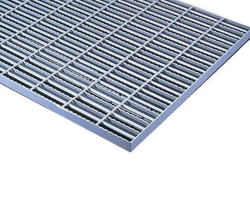

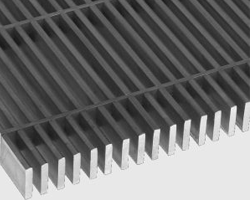

Electro Forged Steel Grating

Ferrograte Electro-Forged Gratings is made of resistance-welding process to create a Rigid Finish to suite the corresponding Environment. The process of manufacturing is done where the Bearing Bars is Resistance-welded at the contact point with the cross bars under a combination of high heat and pressure which is fused together to form a permanent joint. The cross bars provide a high degree of rigidity, yet retain a smooth flat surface for comfortable walking.

Electro-Forged Gratings type is most commonly used compared to all other grating types due to its strength, Durability, cost efficient production and ease of installation. Commonly used in most general Industrial plants as well as Architectural buildings, it has wide applications as Pedestrian Traffic, platforms, safety barriers, drainage covers and ventilation grates Etc.

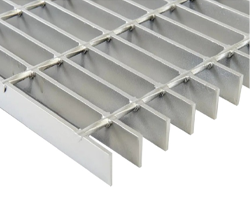

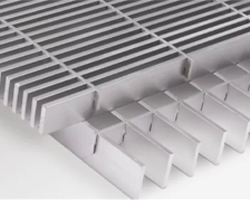

Press-Locked Grating

Press-locked steel bar gratings is a steel grate with a system of interlocking, perpendicular bars, these gratings are ideal floor platforms used for vehicle movements, Architectural applications such as (grilles, dividers and screens), Industrial Walkway access system, etc.

Electro-Forged Gratings type is most commonly used compared to all other grating types due to its strength, Durability, cost efficient production and ease of installation. Commonly used in most general Industrial plants as well as Architectural buildings, it has wide applications as Pedestrian Traffic, platforms, safety barriers, drainage covers and ventilation grates Etc.

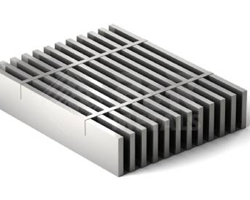

Heavy Duty Gratings

Heavy Duty Gratings commonly used on bridge-building, fire brigade driveways, Fuel Storage units etc., in-order to withstand Heavy loads.

We offer Heavy-duty gratings with bearing bar height up to 120 x 10 mm for Heavy Load environment to withstand load upto 80 tons of (UDL) Uniformly distributed load and 11.5 Tons of concentrated load with a clear span of 1 Mtr Approximately.

A DI Grating A DI Grating is a framework of metal bars used to cover drains, trenches, or channels, allowing water flow while preventing debris or people from falling in. Types:(Trench Gratings (used on roadsides or pavements), Gully Gratings (over road gullies or curb inlets), Heavy-duty Gratings (for industrial or traffic areas)). Load Classes (EN 124 Standard):

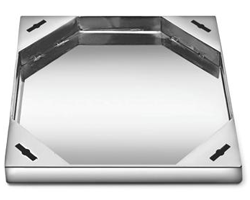

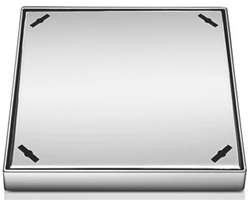

DI Manhole Cover: A manhole gives access to underground utility systems (sewage, stormwater, telecom, etc.). The cover ensures safety and protection from unauthorized access. Types (Solid Top - No openings; used on roads, Ventilated - With holes or slots, Lockable - For security-sensitive areas)

A drain is a pipe or channel that removes excess water or waste from an area. It can refer to: Surface drains - Collect rainwater from roads, rooftops, and pavements. Sewer drains - Carry wastewater from homes and buildings to the sewer system.. Storm drains - Handle rainwater and storm runoff to prevent flooding . Types of drains( French drain,Trench drain, Floor drain, Roof drain)

A manhole is a vertical access point to underground public utilities like sewer lines, stormwater systems, or electrical or telecom conduits.. Provides maintenance access to underground drainage or utility systems..Covered with a manhole cover (usually metal) for safety.Usually found on streets, sidewalks, or in utility areas

FRP product" generally refers to a product made from Fiber-Reinforced Plastic (FRP), a composite material made of a polymer matrix reinforced with fibers (typically glass, carbon, or aramid).

- Gratings and Floor Panels: Used in industrial walkways, platforms, and trench covers.

- FRP Ladders & Handrails: Durable and non-conductive; ideal for industrial and offshore use.

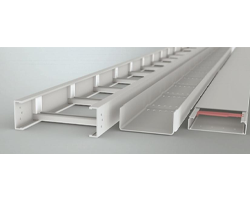

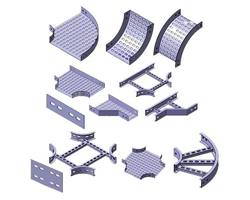

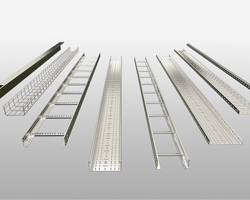

A cable tray is a structural system used to support insulated electrical cables for power distribution, control, and communication. It is commonly used in industrial and commercial buildings.

Types of Cable trays are perforated type cable tray, Ladder type and , Solid bottom Type.

Materials Used : Mild Steel (Painted or Powder Coated) , Hot-Dip Galvanized Steel,Stainless Steel (304, 316),Aluminum,FRP (Fiber Reinforced Plastic)

Slotted channels are structural elements often used in construction, shelving, framing systems, and cable management. They have a U- or C-shaped crosssection with longitudinal slots that allow for easy mounting and adjustment of components. Single (CChannel)

A basic U- or C-shaped channel with one slotted side.

Double (Back-to-Back) Two channels welded together for extra strength.

Double (Face-to-Face) Facing channels joined to form a rectangular box-section.

Half Slot Channel One half of the channel slotted; the other solid for hybrid uses.

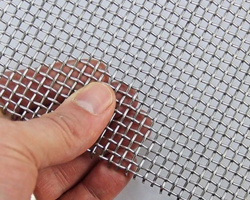

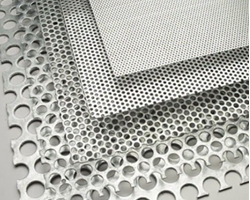

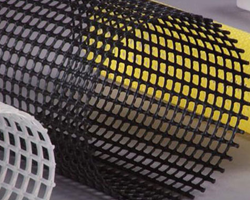

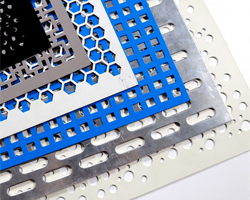

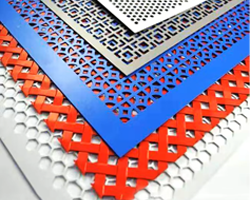

In industry, meshes refer to structured frameworks or networks made of interconnected strands, wires, or elements, and are used in various applications across engineering, manufacturing, and design. Meshes can be categorized based on material Type.

Metal Mesh :

- Woven Wire Mesh - made like fabric; used in filtration, sieving.

- Expanded Metal Mesh - cut and stretched to form a diamond pattern; used in walkways, guards.:

- Perforated Metal Mesh - flat sheets with punched holes; used in screens, enclosures.

- Welded Wire Mesh - wires welded at intersections; used in fencing, concrete reinforcement.

Polymer/Plastic Mesh : Used in lightweight filtering, packaging, erosion control, and gardening.Materials: HDPE, PP, PVC, nylon

Fiberglass Mesh: Lightweight, corrosion-resistant; used in construction, especially wall reinforcement and insulation

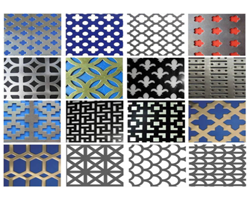

A decorative hole pattern refers to a design that consists of holes arranged in aesthetically pleasing shapes or sequences, commonly used in metal, plastic, or wood panels. These patterns serve both functional and aesthetic purposes—for ventilation, light filtration, weight reduction, or simply ornamentation..

Applications:

- Architectural cladding and facades

- Ceilings and partition walls

- Furniture panels

- Lighting diffusers

- Speaker grilles

- Airflow panels in HVAC

Valves are mechanical devices used to control the flow and pressure of fluids (liquids, gases, or slurries) within a system. They can start, stop, or throttle the flow.

Types of Valves:

- Gate Valve - Used to fully open or fully close the flow; not for throttling.

- Globe Valve - Ideal for regulating flow.

- Ball Valve - Quick shut-off valve using a rotating ball with a bore.

- Butterfly Valve - Compact and lightweight, used for regulating or isolating flow.

- Check Valve - Allows flow in one direction only to prevent backflow.

- Pressure Relief Valve - Protects the system from overpressure.

Applications: Flow control, System isolation, Safety pressure regulation

Flanges are mechanical connectors used to join pipes, valves, pumps, and other equipment in a piping system. They allow for easy assembly and disassembly.

Common Flange Types:

- Weld Neck Flange - High pressure, high temperature, welded to pipe.

- Slip-On Flange - Slips over the pipe and welded on both sides.

- Blind Flange - Used to seal the end of a pipe or valve.

- Socket Weld Flange - For small-diameter high-pressure pipes.

Threaded Flange - Screwed onto the pipe, used where welding is not possible

Flange Face Types:

Flat Face (FF),Raised Face (RF), Ring-Type Joint (RTJ) - Used in highpressure applications

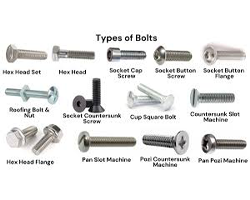

Fasteners" are hardware devices that mechanically join or affix two or more objects together. They are commonly used in construction, manufacturing, electronics, and countless DIY and industrial applications

Common Types of Fasteners:

- Screws: Have a helical thread and are driven into materials. Types: Wood screws, machine screws, selftapping screws, drywall screws.

- Bolts and Nuts: Bolts are paired with nuts to fasten parts through pre-drilled holes. Types of bolts: Hex bolts, carriage bolts, lag bolts. Nut types: Hex nuts, lock nuts, wing nuts.

- Nails: Typically used in wood and softer materials; driven by hammer or nail gun. Types: Common nails, finish nails, brads, roofing nails.

- Rivets: Permanent fasteners used to join metal sheets or plates.Popular in aerospace, automotive, and structural applications.

- Washers: Distribute the load of a threaded fastener and prevent damage. Types: Flat washers, spring washers, lock washers.

- Anchors: Used in masonry or drywall to provide a firm hold. Types: Wall anchors, toggle bolts, sleeve anchors.

- Clips, Clamps, and Pins: Non-threaded fasteners like retaining clips, hose clamps, or cotter pins.

Material Options: Steel (plain, galvanized, stainless), Brass, Aluminum, Plastic or Nylon (for lightweight or non-conductive needs)

"Safety equipment" refers to protective gear and tools designed to minimize risk and protect individuals from injury or harm in various environments, such as workplaces, sports, construction sites, laboratories, and healthcare settings.

Common Types of Safety Equipment:

- Head protection: Helmets, hard hats

- Eye protection: Safety goggles, face shields

- Hearing protection: Earplugs, earmuffs

- Respiratory protection: Masks, respirators

- Hand protection: Gloves (latex, leather, cutresistant, etc.)

- Foot protection: Safety boots, steel-toe shoes

- Body protection: Coveralls, flame-resistant clothing, lab coats

- Fall protection: Harnesses, safety nets, lanyards

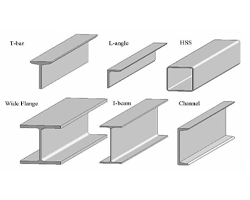

In steel construction, structural items refer to the various steel components used to form the framework of buildings, bridges, industrial facilities, and other infrastructure. Here are the main types:

Primary Structural Steel Items

These carry the main structural loads.

- Steel Beams (I-Beams, H-Beams, W-Beams) : Used for horizontal support. Types: Universal Beam (UB), Universal Column (UC), Wide Flange (WF)

- Steel Columns : Vertical load-bearing members . Common shapes: H-sections, Circular, Square Hollow Sections (CHS/SHS)

- Steel Channels (C-Sections) : Used in frames, bracing, supports

- Respiratory protection: Masks, respirators

- Steel Angles (L-Angles) : L-shaped; used in trusses, frames, bracings

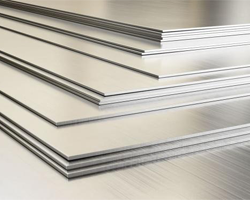

- Steel Plates : Flat steel pieces used in connections, base plates, gusset plates

- Hollow Structural Sections (HSS) : Tubular sections (circular, square, rectangular) , Strong in compression and torsion

Secondary Structural Steel Items

Support or connect primary members.

- Purlins and Girts

- Purlins: horizontal beams in roofs

- Girts: horizontal wall members

- Bracings (Cross, K, V types)

- Provide lateral stability

- Base Plates & Anchor Bolts

- Connect columns to foundations

- Gusset Plates

- Used at joints to connect beams/braces

Miscellaneous Steel Items

For functional or finishing purposes.

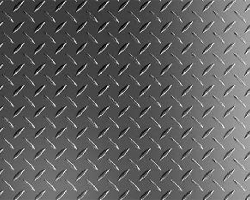

- Gratings and Floor Plates

- Used for industrial walkways

- Handrails and Guardrails

- Safety components

- Staircases and Ladders

- Steel Frames (Door/Window Frames)

- Steel Decking

- Used in composite floor systems

Kitchen Equipment

Interior Works

Bollard

Trolly

Bed

Handrail

Racking System